Home > Products

Products & services

We are a world-leading manufacturer and technology provider for the energy industries globally.

Our Focus:

Specialized OCTG Solutions and Services

Casing and Tubing

We specialize in delivering fully certified Casing and Tubing optimized for the complete range of drilling and production environments, from standard vertical wells to complex horizontal and HPHT applications. Our focus is on providing seamless material integrity, precise threading (API and proprietary), and corrosion resistance, ensuring the structural stability of your wellbore and maximizing long-term production uptime.

- Guaranteed API 5CT compliance and non-destructive testing (NDT).

- Specialized grades for Sour Service (H2S) and critical deep-well deployments.

Big Diameter Conductor Pipe

Our core focus includes providing robust, large-diameter Conductor Pipe essential for initiating offshore and deep onshore well stability. We manage the supply and preparation of welded and seamless conductors up to 48 inches, designed to withstand external loads, maintain hole integrity near the surface, and facilitate rapid, reliable installation across various rig types and installation methods.

- Custom wall thickness and material grades for structural strength.

- Expertise in drive-shoe and piling system compatibility.

Completion Accesories

Our comprehensive supply chain extends to critical Completion Accessories, including Flotation Collars, Stage Cementing tools, Liner Hangers, and Centralizers. We ensure these components are perfectly matched to your casing and tubing string designs, enhancing cement job quality, optimizing running procedures, and guaranteeing the long-term integrity of the production zone. Precision engineering of these components is vital for successful well longevity.

- Supply of custom-machined pup joints and crossover subs.

- Centralizer placement modeling and optimization services.

Spec 7 Drill Pipe Repair

We offer specialized, certified repair and re-threading services for drill pipe tool joints, fully compliant with API Specification 7 standards. Our repair focus extends the lifespan of your valuable drill string assets, ensuring that connections are restored to original manufacturing tolerances, maintaining critical fatigue resistance, and minimizing non-productive time (NPT) associated with equipment failure in high-stress drilling operations.

- Full NDT and dimensional inspection prior to repair.

- Proprietary hardbanding application for enhanced wear resistance.

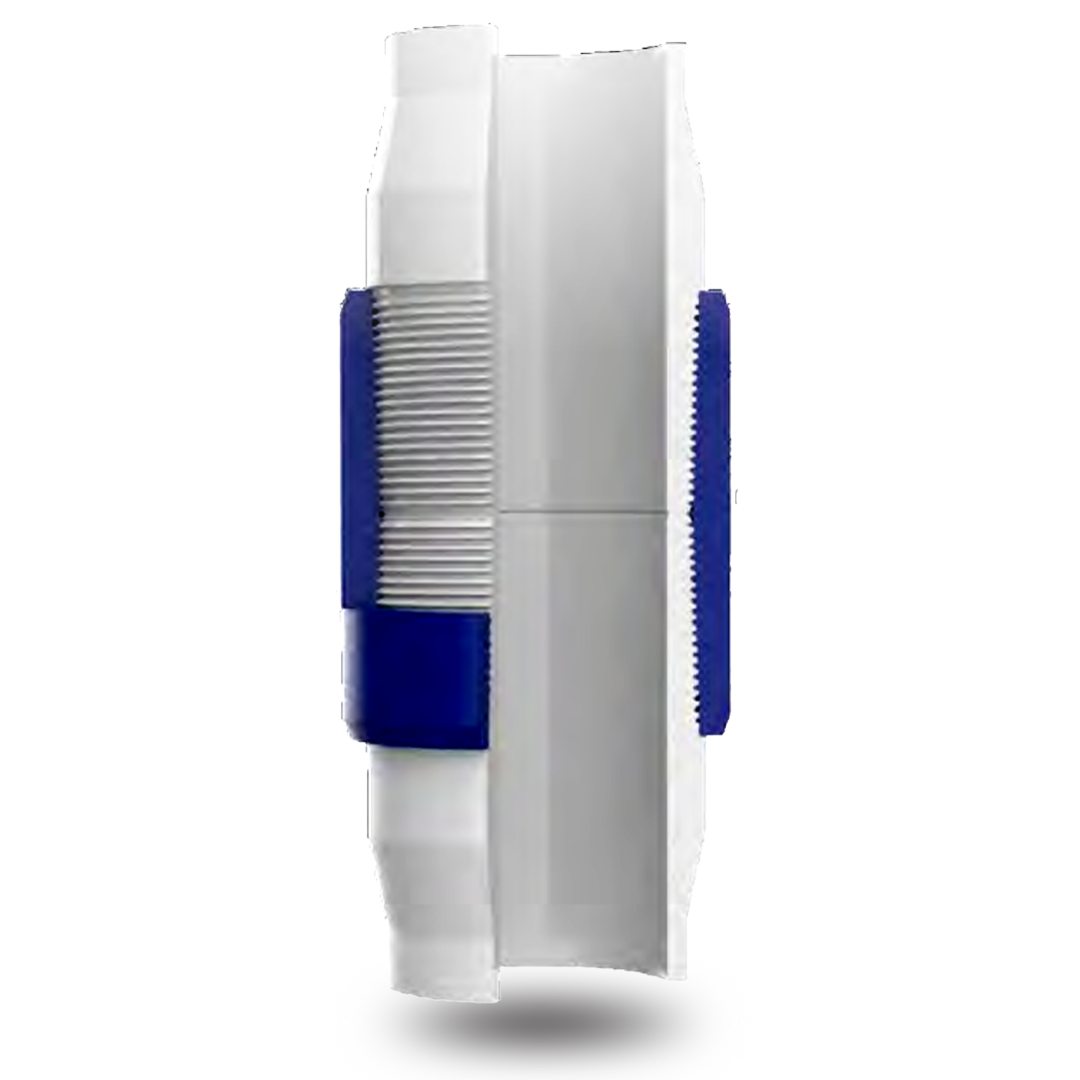

Premium Connection

We prioritize the use and supply of high-performance Premium Connections, offering gas-tight sealing integrity under the most extreme conditions (deepwater, high pressure, high temperature). Unlike standard API threads, our connections are designed with metal-to-metal seals and shoulder features to handle tension, compression, bending, and torsion simultaneously, dramatically reducing the risk of costly well control incidents and ensuring casing and tubing integrity throughout the well’s life cycle.

- Focus on repeatable make-up and high torque capabilities for ERD.

- Complete range of flush, semi-flush, and coupled designs available.

ThreadLock DS

- External & Internal Metal to Metal Seal, ensuring 100% Gas-Tight Seal Integrity.

- Double Shoulder and Thread Stabbing Flanks offer 100% Compressive Rating and High Torque Resistance.

- Negative Load Flank offers Full Head Thread Engagement during high tension load preventing Pin Jump-Out.

- Propierity thread design offers Easy Stabbing and Trouble-Free Running.

- Available tubing size from 2-3/8″ to 4-1/2″

ThreadLock GAIA

- Threaded and Coupled casing/tubing connector.

- Designed for High Compression, High Torque Resistance, High Pressure, and High Temperature Environment.

- Gas-Tight-Metal-to-Metal Seal 100% internal and external pressure rating.

- 100% tension and compression rating.

- Proprietary thread design offer Easy Stabbing and Quick Make-Up Capability.

- Make-Up in 5-6 Turns for casing connections with Single-Start Threads.

ThreadLock DS-EUE

- Fully interchangeable with API EUE.

- Rated to 100% Burst and Collapse Pressure.

- Bored ID and Removal J-Area ensures Smooth Flow Surface and Prevents Turbulance.

- Double Shoulder Design ensures Precise Make-Up Position and offers 100% Compression Rating Along With High Torque Resistance.

- Available tubing size from 2-3/8″ to 4-1/2″

ThreadLock Alfa

- Proprietary thread design with large thread form:

- 2.5 Pitch thread (16″ to 24″ OD)

- 2 Pitch thread (26″ to 36″ OD)

- Quick and Trouble-Free-Make-Up

- External and Internal metal-to-metal seal, ensuring 100% Gas-Tight Seal Integrity, 100% Tension and Compression Rating.

- Anti Rotation achieved by thread interference, “Lock Pins” not required.

- Post-Weld heat treatment and NDT not required.

- Drive-Able Connector.

- Available size from 16″ to 36″

ThreadLock Flush

- Internal Metal-to-Metal Seal offers 100% Internal Pressure Rating.

- External Metal-to-Metal Seal offers Resistance to External Pressure and Prevents Seawater.

- Fatigue Features suitable for Shallow Water Applications.

- Suitable for Tight Annular Clearance

- Design for Drive Pipe Applications